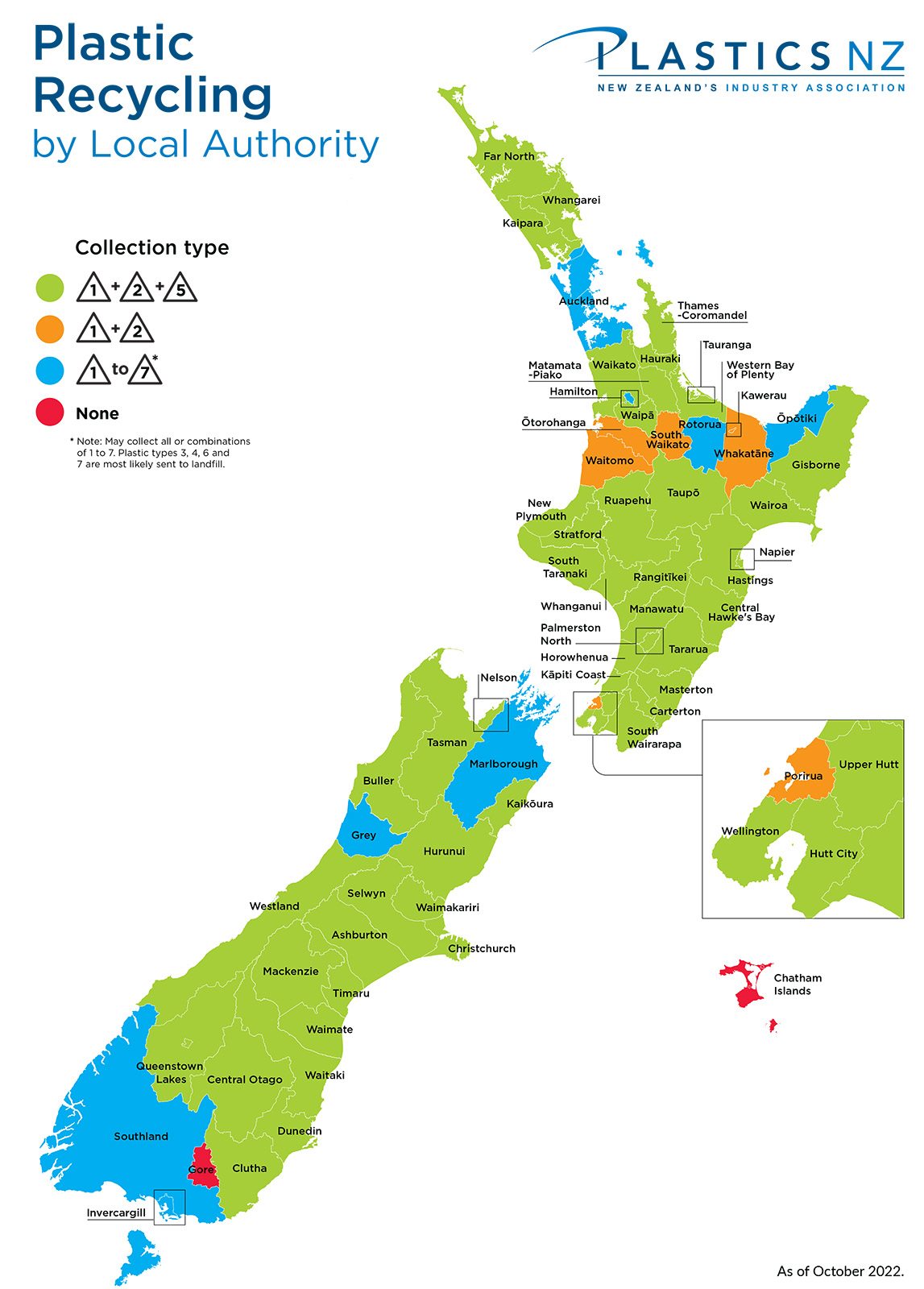

In order to make recycling in New Zealand a reality, all our cities and towns have introduced recycling schemes over the last years, in order to create a net that will catch recyclable materials, and reduce waste going into our landfills.

When it comes to manufacturing plastic packaging, 99% of the waste generated during production is recycled, either by the manufacturer or through a contracted recycling company. At Custom-Pak, we take pride in the fact that nearly all our plastic food packaging is fully recyclable. Most of the containers we thermoform are made using offcuts from post-industrial waste (leftover materials from the manufacturing process) and post-consumer waste (used packaging returned for recycling).

We use:

- r-100

- r-80

- r-50

- r-30

- 100% virgin Apet

- 70% virgin & 30% industrial recycled Apet

However, despite the best efforts of thermoformers and recyclers, the ongoing success of any recycling scheme is not guaranteed because so much depends on education and the attitude of the consumer, who hold the ultimate power in their hands. In other words, when someone finishes their container of muffins, they need to know what to do, then do the right thing, in order for that container to end up being recycled rather than landfilled. You can learn more about the challenges and opportunities of recycling here.

To raise awareness about plastics and their recycling, we’ve provided this Recycling Guide as a resource which explains what the recycling numbers on plastic containers mean, the properties and uses of each type of plastic, and what each number can be recycled into. For more information on where to recycle in your community, please contact your local council or check their website for up-to-date details on your local collection system.

Kerbside Collections Guide

Download

| Symbol | Type of plastic | Properties | Common uses | Recycled in |

|---|---|---|---|---|

|

RPET Recycled Polyethylene Terephthalate |

The recycling process produces consistent, pure quality of recycled plastic. Safe, clean and eco-friendly, it requires less energy to manufacture products made out of recycled plastic | Water bottles, food containers, textiles, sleeping bags, upholstery foams, industrial strapping, carpets | PET Plastic Containers |

|

PET Polyethylene Terephthalate |

Clear, tough, solvent resistant, barrier to gas and moisture, softens at 70°C | Soft drink and water bottles, salad domes, biscuit trays, salad dressing and oeanut butter containers, fleece clothing and geo-textiles | Pillow and sleeping bag filling, clothing, soft drink bottles, carpet |

|

HDPE High Density Polyethylene |

Hard to semi-flexible, resistant to chemicals and moisture, waxy surface, opaque, softens at 135°C, easily coloured, processed and formed | Crinkly shopping bags, freezer bags, milk bottles, ice cream containers, juice bottles, shampoo, chemical and detergent bottles, buckets, rigid agricultural pipe, milk crates | Recycling bins, compost bins, buckets, detergent containers, posts, fencing, pipes |

|

PVC UnPlasticised Polyvinyl Chloride PVC-U Plasticised Polyvinyl Chloride PVC-P |

Strong, tough, can be clear, can be solvent welded, softens at 75°CFlexible, clear, elastic, can be solvent welded | Cosmetric containers, electrical conduit, plumbing pipes and fittings, blister packs, wall cladding, roof sheeting, bottlesGarden hose, shoe soles, cable sheathing, blood bags and tubing, watch straps, commercial cling wrap | Flooring, film and sheets, cables, speed bumps, packaging, binders, mud flaps and mats |

|

LDPE Low Density PolyethyleneLLDPE Linear Low Density Polyethylene |

Soft, flexible, waxy surface, translucent, softens at 80°C, scratches easily | Cling wrap, rubbish bags, squeeze bottles, black irrigation tube, black mulch film, rubbish bins, shrink wrap | Rubbish bin liners, pallet sheets, slip sheets |

|

PP Polypropylene |

Hard but still flexible, waxy surface, softens at 145°C, translucent, withstands solvents, versatile | Dip pottles and ice cream tubs, potato chip bags, straws, microwave dishes, kettles, garden furniture, lunch boxes, blue packing tape, automotive parts | Pegs, bins, pipes, pallet sheets, oil funnels, car battery cases, trays |

|

PS Polystyrene |

Clear, glassy, rigid, brittle, opaque, semi-tough, softens at 95°C. Affected by fats and solvents | CD cases, plastic cutlery, imitation ‘crystal glassware’, low cost brittle toys, video cases, water station cup, safety helmets | Coat hangers, coasters, white ware components, stationery trays and accessories |

|

EPS Expanded Polystyrene |

Foamed, light weight, energy absorbing, heat insulating | Foamed polystyrene hot drink cups, hamburger take-away clamshells, foamed meat trays, protective packaging for fragile items, insulation, insulation panels | Car parts, concrete aggregate, plastic timber |

|

OTHERS Letters below indicate ISO code for plastic type including SAN (styrene, acrylonitrile), ABS (Acrylonitirite butadine styrene), PC (polycarbonate), Nylon, degradable plastic e.g. PLA |

Includes all other resins, multi materials (e.g. laminates) and degradable plastics. Properties dependent on plastics or combination of plastics | Packaging, car parts, appliance parts, computers, electronics, water cooler bottles, medical devices | Car parts, concrete aggregate, plastic timber |