Because Custom-Pak values the world we live in, we’re working towards a future plastic packaging manufacturing plan that will close the loop on the plastics lifecycle, from raw materials to recycling, to ensure our process is a sustainable one.

The term “circular economy” has been coined to express the difference between what economists would call a “Linear System” where we make and use goods, then simply dispose of them, and a cyclic system where an end product becomes the new raw material. In the old linear approach, the items we buy have typically been designed and manufactured without consideration for the resources consumed or what happens when they’re at the end of their useful life. This style of manufacture does not design products to be reused, repaired, refurbished or recycled, it simply assumes that the item will be sent to landfill once used, creating a straight line from the cradle to the grave.

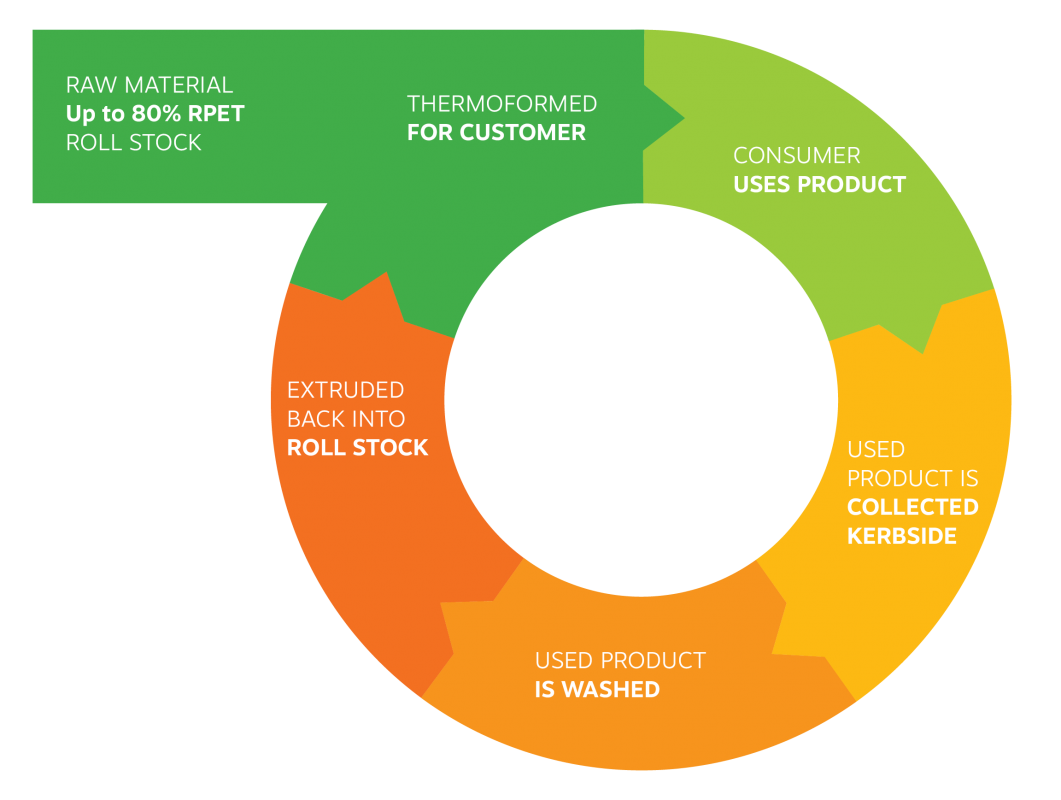

By contrast, in a circular economy we keep resources in a circle-of-life cycle for as long as possible to gain the most from the resources we’ve used, extend their useful life as long as possible, and make products that can be easily repaired, refurbished or recycled.

The core principles of a “circular economy” are based on three key actions – designing out waste & pollution, keeping products and materials in use, and regenerating natural systems. At Custom-Pak, our ultimate goal is to help New Zealand move towards a more desirable circular economy which will minimise plastic waste going to landfill and limit the use of non-renewable energy sources.

One way we can achieve this goal is to focus on a closed-loop packaging system that recycles packaging so it can be reinstated back into 100% recycled material.

The recycled PET plastic (RPET which can be a mixture of PCR* and PIR**) our products are made from can actually be recycled several times and remain suitable for food packaging. Even then, when food packaging is no longer an option, this material can be recycled once more into other plastic products, like outdoor furniture and door mats.

* PCR – Post Consumer Recycled content

** PIR – Post Industrial recycled content

Our consumable resources are also under scrutiny as we scope for renewable solutions that will benefit our people and our planet and we’ve been mindful about designing our business to sustainably meet the needs of our markets in different geographical locations. By operating two plastic packaging manufacturing plants, one in Auckland and the other in Christchurch, we can more efficiently service customers in both locations and significantly reduce our use of transport without the need to freight orders between islands.

Whether you are a grower, distributor, food retailer or an exporter, being responsible about your plastic packaging choices is now an essential part of doing business successfully and sustainably. You are welcome to come and talk to us here at Custom-Pak about the new era of plastic packaging responsibility, we welcome your thoughts and enquiries.

Custom-Pak Plastic Products Limited is a New Zealand company operating our business from the mainland, although whether you’d say the “mainland” is the North Island or the South really depends on where your allegiance lies. Fortunately, we’ve got both bases covered.

Southerners refer to their island as New Zealand’s heartland. It’s the beating heart of our country’s rural way-of-life, where living and working on land and sea produces the beef, lamb and seafood New Zealand is famous for around the world. Christchurch is the South Island’s main centre, but small country towns with a focus on farming and growing make up the backbone of the local communities and provide the foundation of the rural economy. If you’re roaming around the South Island, make sure you pack your Drizabone coat and redband gumboots in the ute, because you just might need them.